A West Texas operator sought a solution to optimize drilling capabilities

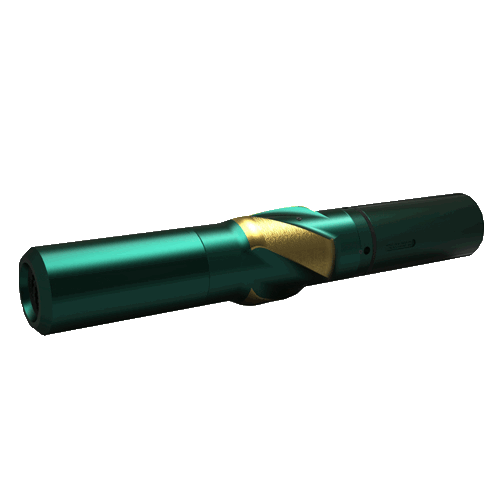

For this application, two wells utilized Expro’s 800 series HI TOOL® Harmonic Isolation Tool. The tool was placed above the RSS and MWD/LWD in order to protect these critical BHA components and support increased drilling parameters

By reducing wear, the HI TOOL® extends the life of BHA components. It also allows the entire face of the bit to stay more directly engaged with the rock which results in a higher ROP

The two wells utilizing the HI TOOL® were compared to two offset wells without any vibration mitigation strategies, with all wells operating within similar parameters. The wells with the HI TOOL® benefitted in multiple ways, including increased ROP, increased section length, reduced of number of trips, and reduced time to complete the lateral sections

Benefits included:

- Increased ROP by an average of 39%

- Increased section length by an average of 4200 ft.

- Reduced the average number of trips by 2.5

- Wells with the HI TOOL® completed the operation an average of five days sooner