- Home

- Products & services

- Well Construction

- Well Flow Management

- Subsea Well Access

- Subsea Test Tree Assemblies

- Intervention Riser System

- Riserless Well Intervention System

- Light Well Intervention Vessel

- PRT Offshore

- Motion Compensated Coiled Tubing Lift Frame

- Inline Compensator 600T

- Inline Compensator 220T

- ProFrame™ Coiled Tubing Lift Frame

- HOSS™ Wireline Lift Frame

- Gate Valve Flowhead

- Surface Test Tree

- Quick Union

- Lubricator Valve

- Subsea Landing String

- Subsea Controls

- ProComp™ Tower

- Intervention Work Tower

- Blue Sky Tower

- Accessories & Rental Tools

- Contact Us

- Well Intervention and Integrity

- Sustainable Energy Solutions

- Case studies

- Media hub

- Careers

- Citizen of the world

- Contact

- Our 2023 Sustainability Review

- About Us

- Investors

- Locations

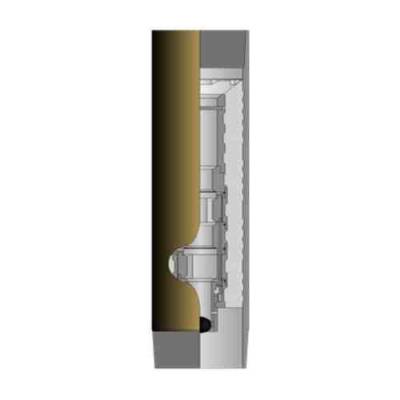

ULTRASEAL™ Auto-Fill Float Equipment

The ULTRASEAL™ Auto-Fill Float Equipment is designed for running and cementing tight-tolerance 9-5/8” and larger casing/liner strings. Industry-leading technology combined with exclusive features results in the most capable and flexible auto-fill system available.

Features and Benefits

Expro’s Proprietary, dual composite flapper valves allow high backpressure holding capability and allows flexibility for the design of the primary cement job for improved zonal isolation

Large ID through valves and ball seat maximizes running speeds and minimizes surge pressure to decrease costly mud loss and increase rig time savings

Removable ball seat allows conversion flow rate and pressure to be easily adjusted prior to running downhole, enabling real-time adaptability to changing wellbore conditions

Activation ball can be trapped in place or dropped from the surface for improved operational flexibility

When trapped in place, activation ball is designed to stay off seat to mitigate the risk of premature conversion from sudden casing movement

“Stackable” without the need for modification; one deactivation ball can trip two or more collars to remove the need to run a baffle collar in between assemblies to catch an auto-fill tube

Anti-rotation feature on landing surface prevents plug spinning to allow for faster drill out

Tapered landing surface is compatible with Franks ULTRALATCH™ Subsurface Release and other plug systems to allow for additional plug set options

Find detailed information about our products and services.