- Home

- Products & services

- Well Construction

- Well Flow Management

- Subsea Well Access

- Subsea Test Tree Assemblies

- Intervention Riser System

- Riserless Well Intervention System

- Light Well Intervention Vessel

- PRT Offshore

- Motion Compensated Coiled Tubing Lift Frame

- Inline Compensator 600T

- Inline Compensator 220T

- ProFrame™ Coiled Tubing Lift Frame

- HOSS™ Wireline Lift Frame

- Gate Valve Flowhead

- Surface Test Tree

- Quick Union

- Lubricator Valve

- Subsea Landing String

- Subsea Controls

- ProComp™ Tower

- Intervention Work Tower

- Blue Sky Tower

- Accessories & Rental Tools

- Contact Us

- Well Intervention and Integrity

- Sustainable Energy Solutions

- Case studies

- Media hub

- Careers

- Citizen of the world

- Contact

- Our 2023 Sustainability Review

- About Us

- Investors

- Locations

SurgeCure®

Autofill inner string

The increase in downhole pressure when a tight tolerance casing or liner string is run in hole – surge – can be detrimental to any well construction project, including risking uncontrollable losses and compromising wellbore integrity or alternatively demanding unacceptably slow tripping speeds.

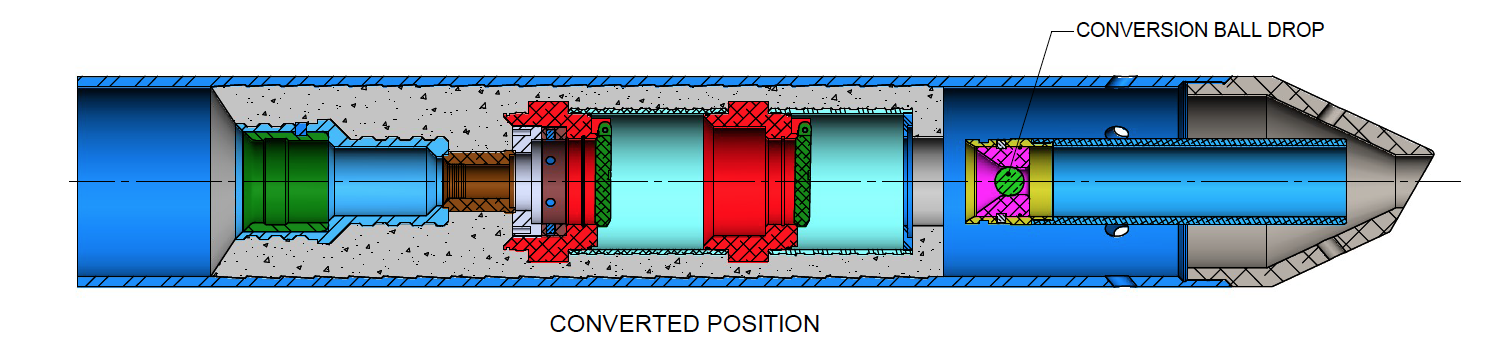

Expro’s SurgeCure® technology has been developed to overcome the challenges in deploying and cementing long casing strings or liners with small annular clearances, particularly in weak formations, whilst offering all of the benefits of the SeaCure® cementing system.

Autofill inner string with SurgeCure®

SurgeCure® utilises autofill shoes, inflow diversion and the field proven SeaCure® inner-string cementing technology to maximise autofill flow capabilities to minimise surge pressures, reduce casing deployment risks and improve overall operational efficiencies.

Standard float equipment is produced in autofill configuration to provide all of the benefits of an inner-string SeaCure® cement operation in tight casing tolerance or reduced equivalent circulating density (ECD) window sections.

SurgeCure® Value

- Run casing or liners with tight diametric tolerances

- Reduce surge pressure while running casing or liners

- Run as part of SeaCure® operation

- Improve running speeds

- Minimise mud losses

- Prevent break down of weak formation

Interested in knowing more about SurgeCure®?

Find detailed information about our products and services.